Everyone who owns an FDM 3D printer wishes they could print their projects faster without sacrificing quality. Fortunately, there are custom firmware options that can help you improve the print speeds of even the best 3D printers out there.

Klipper is one of the most popular options for speed and quality, but it’s not a beginner-friendly option. It’s a custom firmware that you must first configure onto a single-board computer (like a Raspberry Pi) that works with your printer’s mainboard to boost the available processing power.

Enter the Creality Sonic Pad (opens in new tab). The Sonic Pad is a Klipper (opens in new tab) controller that includes everything you need to calibrate and optimize your printer in one easy package. Your printer will still need to be Klipper compatible, but assuming it is, the Sonic Pad takes a lot of the stress and effort out of the process as you don’t need to source your own single-board computer.

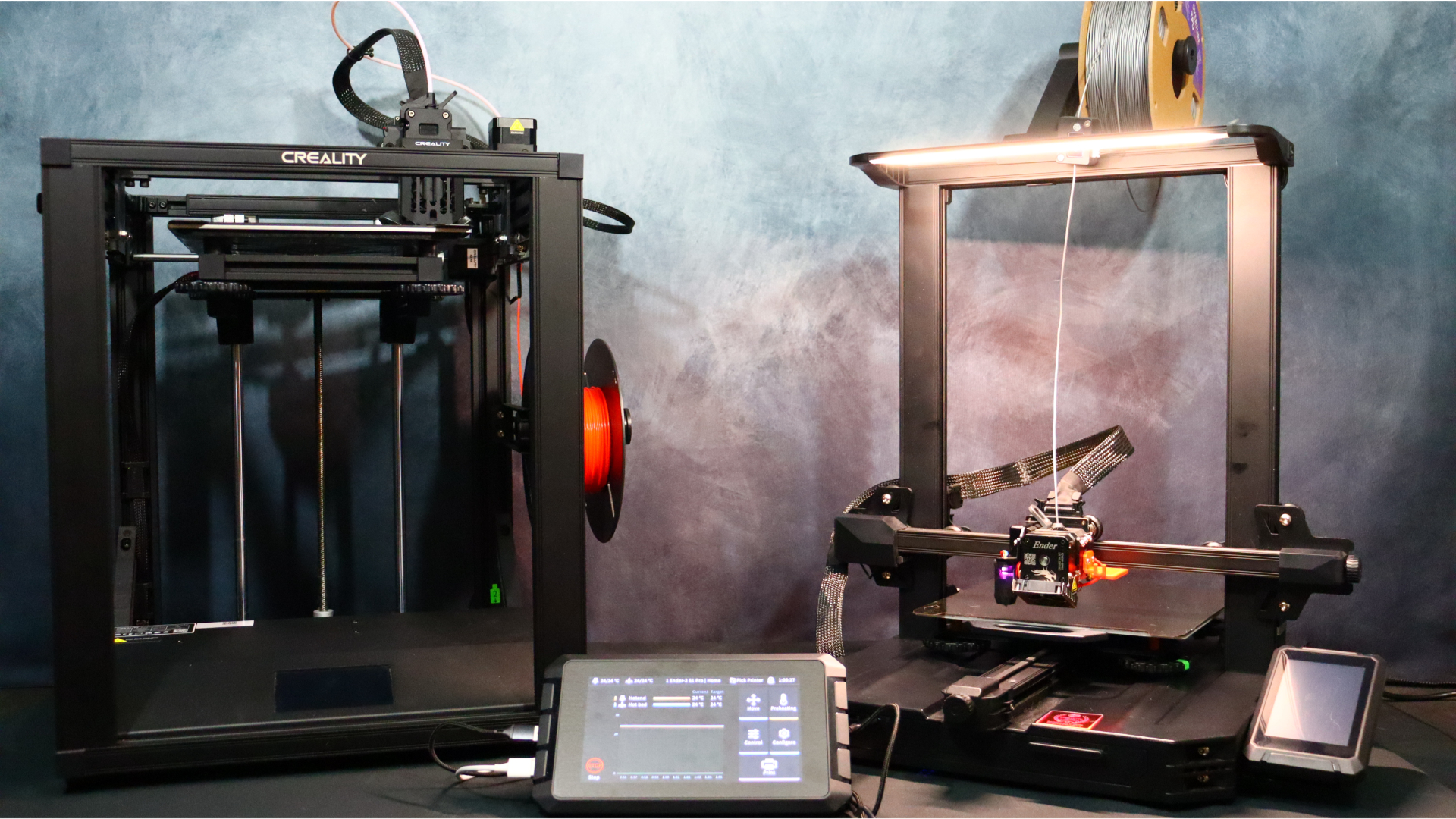

Let’s take a look at the Sonic Pad and see how simple it is to switch over to Klipper and get the printer calibrated and printing. For this article, we’ll be using our Ender 3 S1 Pro and the newly supported Ender 5 S1. Let’s see how much faster we can print and how the quality holds up.

Creality Sonic Pad: Design

The Creality Sonic Pad has a 7-inch color touch screen with a 1024 x 600 resolution. The body is constructed of hard plastic. It’s light, but it has a premium feel and build quality. Two status LEDs and a power button are located on the right side of the unit.

Two USB ports are located on the left side. Around the back are two more USB ports (one labeled camera), an Ethernet port, and a PS/2 port for connecting the accelerometer for resonance calibration. Finally, the pad is held upright by two kickstand legs.

Creality Sonic Pad: Setup

The Sonic Pad is a simple plug-and-play device. The first thing you’ll do after turning on the pad is select your printer model. The Sonic Pad is compatible with several Creality printer models, as well as other printers that can run Klipper firmware. Creality includes instructions for adding support for models from other manufacturers. The printer.cfg file that Klipper requires for the firmware is the most important thing you’ll need.

Following your model selection (in our case, the Ender 3 S1 Pro and Ender 5 S1), you must follow the on-screen prompts and insert an SD card into the indicated USB port to install the Klipper firmware for the printer. Insert the SD card, then power on the printer and connect the USB cable to the pad and printer.

After flashing the printer, connect it to the Sonic Pad and the on-screen guide will walk through the rest of the setup process. The entire procedure only takes about 10 to 15 minutes to complete. Setting your z offset, manually leveling the bed, and then an auto-level are the longest steps in the process; however, the auto-level is much faster than the stock version, which is a plus.

After you’ve completed the initial setup, you can proceed with some of the more advanced calibrations. The first step is to run PID (Proportional, Integral, and Derivative) tuning for both the hotend and the bed. These options can be found in the settings and advanced menus.

After that, we like to run the resonance compensation calibration, which is found right under the PID options. You will need a bracket for the sensor to sit on to run this test, which you can find the file for on the USB drive. Simply slice and print the model; we did this on the Ender 3 S1 Pro before converting it to Klipper.

The bracket will be attached to the hotend with the two longer screws included with the sonic pad; once attached, the accelerometer sensor will be plugged into the PS/2 port on the back of the pad before proceeding with the test. The hotend will begin to vibrate once the test begins.

The test will take several minutes to complete, after which you will be asked to move the sensor to the bed. This can be challenging because the hotend does not move out of the way. Before proceeding, we secured the sensor to the bed with painters’ tape. The bed will begin to vibrate, and once completed, the pad will calculate the best input shaper and acceleration to use for the heater.

Creality Sonic Pad: Performance & print quality

We sliced some models for the Ender S1 Pro at 140 mm/s once everything was ready. The first model is a Flexi Yeti from Flexifactory, followed by a photo of the same print on the stock firmware setup at 60 mm/s. Both prints were flawless; there were no issues with the joints and no other flaws. The Flexi Yeti took approximately 3.4 hours to print using the Sonic Pad, compared to the 6.3 hours in took on stock firmware.

The Sonic Pad was able to keep the print quality while increasing the print speed slightly more than twice as fast as the stock firmware. The results speak for themselves; because the first yeti printed so well, we decided to print the baby flexi yeti at the same speed (140 mm/s), and the quality was excellent once again. The Baby Flexi’s print times dropped to around 1.5 hours with the Sonic Pad, from 3 hours on stock.

The first print we decided to try was an Eastman bust. This is an incredible Skeletor bust that was printed in Creality HP Ultra PLA at a print speed of 200 mm/s on the inner walls and 100 mm/s on the outer walls. We couldn’t be happier with the results, which took half the time it would have taken on the stock firmware – 6.5 hours, down from 13 hours.

We decided to move the Ender 5 S1 into place and set it up with the Sonic Pad for the next test prints so we could run both Enders at the same time. To add a printer, simply click Switch Printer at the top of the screen, followed by Add. We quickly set up the Ender 5 S1 by following the same steps as before.

For the final test model, we went with another bust from Eastman’s incredible collection, this time the Hellboy bust. The orange PLA worked really well, and with the same settings as the previous model, the results are, to say the least, satisfying. Once again, print times were cut in half – 6.5 hours, down from 13 hours

| Row 0 – Cell 0 | Sonic Pad | Stock firmware | % print time decrease |

| Flexi Yeti | 3.4 hours | 6.3 hours | 46% |

| Baby Yeti | 1.5 hours | 3 hours | 50% |

| Skeletor Bust | 6.5 hours | 13 hours | 50% |

| Hellboy Bust | 6.5 hours | 13 hours | 50% |

Should you buy the Creality Sonic Pad?

The Creality Sonic Pad is a must-have if you have a compatible FDM printer. It offers vastly increased print speeds without sacrificing quality. Combine that with the ease of setup and calibration, as well as the included accelerometer for tuning the input shaper and acceleration, and it’s a clear winner in our book.

The Sonic Pad is a wise investment for people with multiple printers too, because it can support up to four printers or a combination of two printers and two cameras on a single pad. The included Web UI is also a nice touch, as it allows you to monitor and make changes on the fly – something that isn’t possible with a stock Marlin firmware printer.