Work is progressing on a vital part of NASA’s Mars sample return plans.

The Mars Ascent Vehicle (MAV) is a small, lightweight, two-stage solid-propellant rocket with a big assignment: blast rock, sediment and atmospheric samples off Mars in the early 2030s, in the first-ever rocket launch from the surface of another planet.

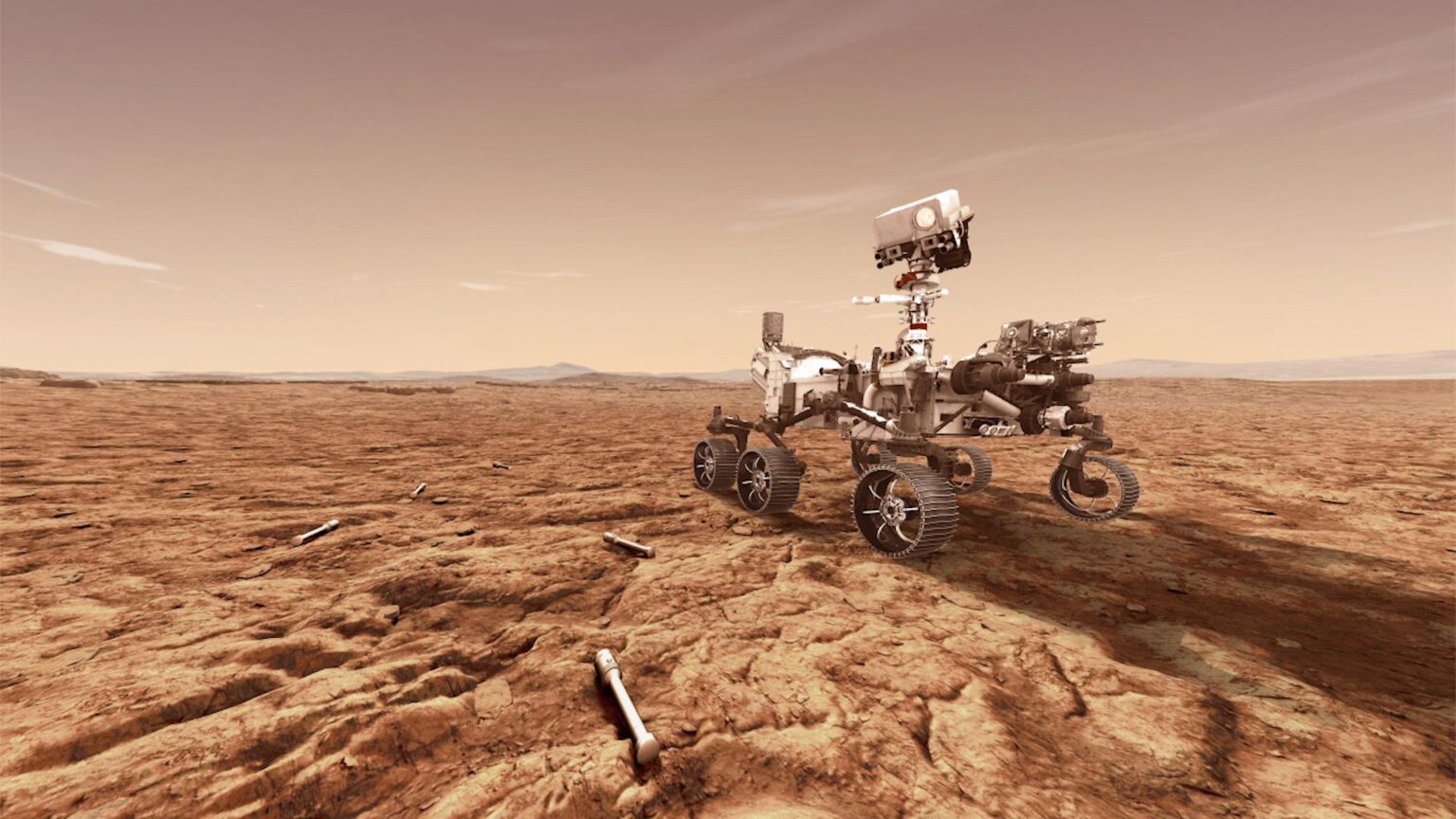

The MAV, which is being developed by Lockheed Martin Space of Littleton, Colorado, will be packaged with NASA’s Sample Retrieval Lander (SRL), another big part of the sample return campaign. The two-in-one spacecraft — MAV and SRL — will touch down near or in Jezero Crater, the spot where NASA’s Perseverance rover is already busily gathering Mars samples. A second lander, carrying a European Space Agency (ESA) “fetch rover,” will touch down in the same area as well.

Related: Perseverance rover’s Mars samples now won’t make it to Earth until 2033 at best

The fetch rover will bring Perseverance’s samples to the MAV. The rocket will launch into Mars orbit, where ESA’s Earth Return Orbiter (ERO) will grab its sample-filled container. The ERO will then haul the samples to Earth, ejecting them via an Earth Entry System (EES) for a high-speed, no-parachute landing in the Utah desert in 2033, if all goes according to plan.

That sample return capsule, also designed by Lockheed Martin, is made of a lightweight composite structure, enveloped by a special thermal protective material provided by NASA’s Ames Research Center in California’s Silicon Valley.

Humanity has never returned pristine samples from Mars before, and there are significant challenges facing the team that’s trying to make it happen, explained Steve Sides, Lockheed Martin’s senior program manager for the Mars Ascent Vehicle Integrated System (MAVIS) based in Huntsville, Alabama.

Aim it, point and shoot

The MAV is less than 10 feet tall and 1.5 feet in diameter (3 by 0.5 meters), Sides told Space.com. “It’s a relatively small rocket,” he said, “so aim it, point and shoot.”

Lockheed Martin Space is providing NASA with multiple MAV test units and a flight unit. Work under the contract includes designing, developing, testing and evaluating the integrated MAV system and designing and developing the rocket’s ground support equipment.

The cost-plus-fixed-fee MAVIS contract has a potential value of $194 million and will extend for six years. The clock is ticking. The SRL-MAV duo are currently scheduled to launch in 2028 from NASA’s Kennedy Space Center in Florida, kicking off the long trek to the Red Planet.

“The goal is to land there early in the year and take off before [Martian] winter hits,” Sides explained.

Related: NASA’s Perseverance Mars rover nabs 8th rock sample on the Red Planet

Loft and light

A novel aspect of the MAV design is the use of a gas-generated concept — a vertically ejected controlled tip-off release, or VECTOR for short. It’s a loft-and-light technique spearheaded by engineers at NASA’s Jet Propulsion Laboratory in Southern California, which is building the SRL.

The MAV will carry about 30 sample tubes, which will be loaded from the fetch rover into the rocket by the SRL’s robotic arm. The MAV will then be tossed into the thin Martian air, roughly 18 feet (5.5 m) above the lander that doubles as a launch pad. At that point, the rocket’s first-stage motor will ignite, Sides said.

“Throwing a rocket up and getting it to light has been done before, but never on Mars,” said Sides. The VECTOR approach minimizes blowback and interference with the SRL, he explained.

Once ignition occurs, the rocket high-tails it towards Mars orbit. “Ultimately, the MAV gets on the order of about 4,000 meters per second [8,950 mph, or 14,400 kph] to reach Mars escape velocity,” Sides said.

After first-stage separation, spinup motors on the second stage activate to stabilize the still-blazing stage, and then spin down. “We’ll coast for 10 to 15 days,” Sides said. During that time, a beacon on the upper stage will broadcast its whereabouts for rendezvous and capture by a system aboard the ERO.

Early and concrete step

“We’ve never launched a rocket from Mars, so there’s a lot of technology involved here,” Sides said. “But we’re also going to get a lot of science from those Mars samples.”

Indeed, returning samples from Mars has been on NASA’s to-do list for decades. “It’s hard, but the technology and time to do this is right. We just have to go do it,” Sides said. “I wouldn’t put it in the easy category … but I wouldn’t put it in the ‘unobtainium’ category,” he added. “We have the capability now.”

Thomas Zurbuchen, the associate administrator for science at NASA headquarters in Washington, said in an agency statement (opens in new tab) in February that committing to the MAV represents “an early and concrete step to hammer out the details of this ambitious project not just to land on Mars, but to take off from it.”

Bits and pieces

Those bits and pieces of Mars will land with a thud in the Utah desert.

To test the Mars Sample Return EES, engineers have carried out a series of drop tests at the Utah Test and Training Range, the lakebed site where the samples will touch down.

During recent tests, a manufacturing demonstration unit (MDU) of one potential design for the EES aeroshell was dropped from an altitude of 1,200 feet (opens in new tab) (365 m), giving it time to reach the intended landing speed.

“The MDU was very stable during descent — it didn’t wobble around a lot, and it landed successfully, in the sense that there was no structural damage and it survived impact as expected,” NASA’s Jim Corliss, a Mars Sample Return EES chief engineer, said in an agency statement in April (opens in new tab).

“We are nearing the end of the conceptual phase for this Mars Sample Return mission, and the pieces are coming together to bring home the first samples from another planet,” Zurbuchen said in the February statement. “Once on Earth, they can be studied by state-of-the-art tools too complex to transport into space.”

Leonard David is author of the book “Moon Rush: The New Space Race,” published by National Geographic in May 2019. A longtime writer for Space.com, David has been reporting on the space industry for more than five decades. Follow us on Twitter @Spacedotcom (opens in new tab) or on Facebook (opens in new tab).